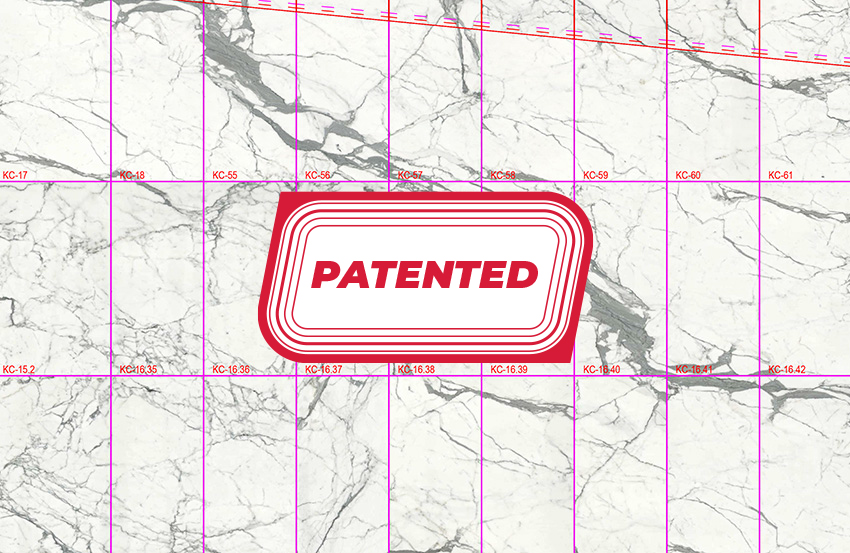

After selecting the stone material, we employ precise cutting and laying techniques that follow the authentic grain pattern, ensuring a seamless finish reminiscent of the original quarry appearance.

Statistically, stone fabrication results in around 45% waste per block

With the virtual dry lay – which we patented – the waste is reduced by an impressive 20%. Clients use this technology to map each block comprehensively and assign panels to specific sections, optimizing resource utilization.

Additionally, our physical dry lay process cross-references the digital design to minimize inefficiencies, ensuring a smooth transition from concept to reality.

This production approach enhances sustainability while preserving the natural beauty of stone and minimizing waste.